Background & Specifications - According to the latest requirements of national safety supervision, gas tank belongs to the "two key and one major" major source of danger of dangerous chemicals, gas tank piston safety monitoring system can meet the national emergency center and local emergency management department safety requirements, its safety control display screen should be dynamic display and have alarm and safety chain function. The whole converter gas system can run safely for a long time.

Application scenario: dry type, wet type gas tank (Man type, Wiggins type, Colon type gas tank)

The application of laser ranging sensor in the field of safety monitoring is more and more extensive, among which the monitoring of gas tank piston displacement is an important safety measure.

This paper introduces the application of SK-Pro series laser ranging sensors in the field of piston safety monitoring.

SK-Pro series laser ranging sensor is a high-precision and reliable equipment, its accuracy can reach 1mm, the frequency is 30Hz, the range of 30, 60, 100m for choice. This series of sensors uses laser for human eye safety and has a wide range of applications in the field of liquid level measurement. At the same time, the series of sensors support serial port, CANBUS, 4-20mA analog, MODbus and other interfaces, and can realize data transmission and sharing with various industrial control platforms and monitoring systems.

Advantages and characteristics

· Both: measuring range 100m, high precision 1mm, resolution 0.1mm, fast measurement 30Hz

· Resistance to outdoor bright light

· High stability; Reporting fewer errors

· Industrial protection

· Rich output interface

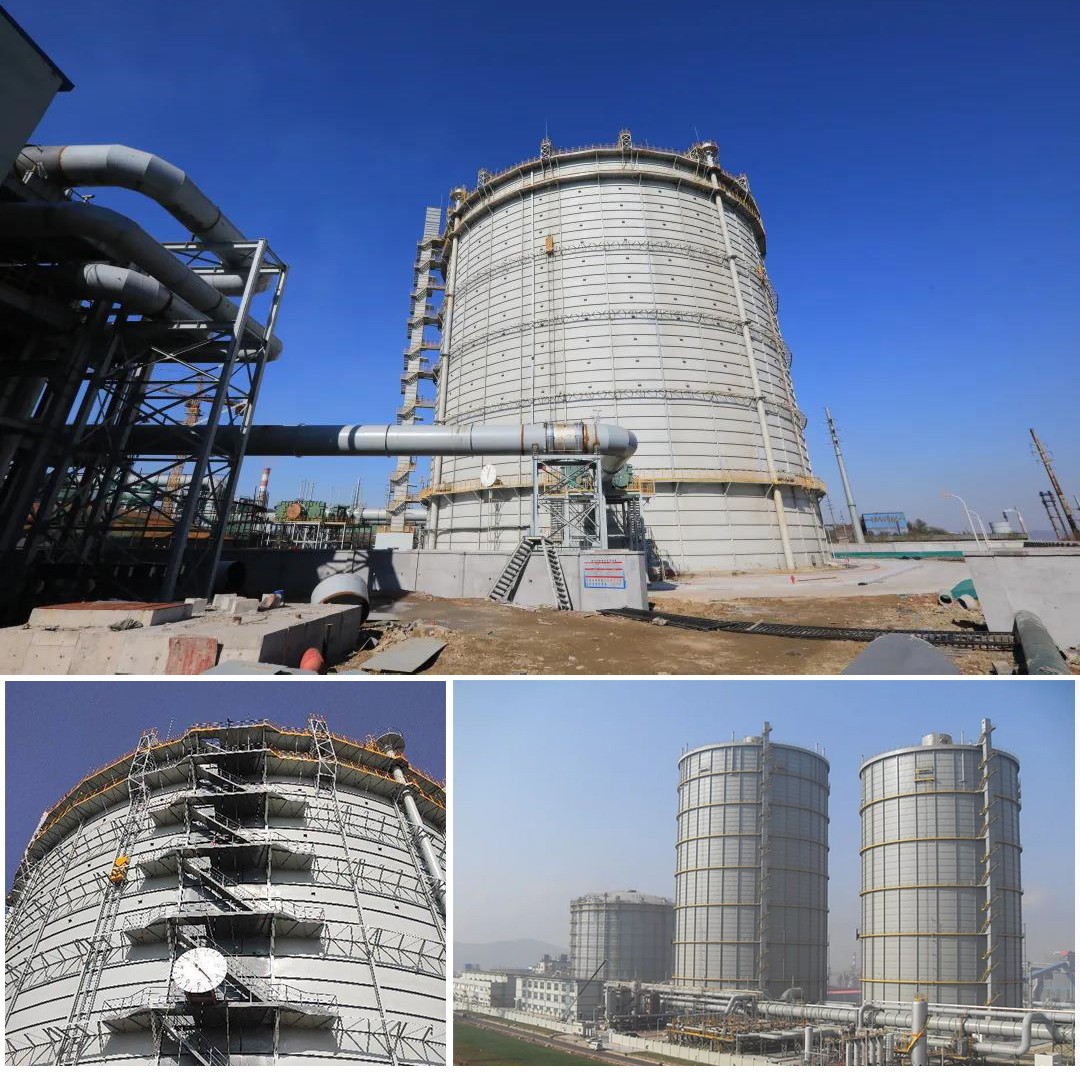

As one of the important facilities of iron and steel enterprises, gas tank plays an important role in gas storage, regulating gas pipe network pressure, rational use of energy, reducing environmental pollution and so on.

The safe operation of gas tank plays an important role in the recovery and utilization of converter gas and the reduction of energy consumption of converter smelting. Piston is one of the key components in the working process of gas tank, and its vertical degree directly affects the normal work and operation safety of gas tank.

In order to solve this problem, we use the laser ranging sensor, which has the advantages of no contact, no intrusion, small measurement face. At the same time, the sensor has good laser coherence, strong directivity, small divergence Angle, energy concentration, good penetration, weak signal processing ability, unique software algorithm and precision optical lens, so as to achieve higher accuracy and better measurement effect, to ensure the safe operation of the gas tank.

In piston safety monitoring, SK-Pro series laser ranging sensors can measure the height of the liquid level inside the gas tank in real time, and transmit the data to the monitoring system to realize the real-time monitoring of piston displacement.

This series of sensors adopts high-precision laser ranging technology, which can be used for non-contact liquid level measurement inside the gas tank, avoiding the potential safety risks and errors caused by traditional contact sensors. In addition, the SK-Pro series of laser ranging sensors also have the advantages of high precision, rapid response and wide measuring range. This series of sensors is very convenient to install and maintain, and can help users quickly realize the equipment upgrade, and has a long life and excellent stability.

To sum up, the application of SK-Pro series laser ranging sensors provides an efficient, accurate, safe and stable solution for gas cylinder piston displacement monitoring. The application of this sensor in the field of piston displacement monitoring is expected to bring more convenience and guarantee for the safety management and production of gas cylinders.